Belt Cleaners That Clean Better, Last Longer, Cost Less

Martin Engineering provides efficient belt cleaners that eliminate carryback, enhancing safety and productivity across industries. Our range includes washing systems, brush cleaners, food-grade scrapers, and high-temperature options, tailored for unique environments.

CleanScrape® Primary Cleaners

Martin Engineering provides efficient belt cleaners that eliminate carryback, enhancing safety and productivity across industries. Our range includes washing systems, brush cleaners, food-grade scrapers, and high-temperature options, tailored for unique environments.

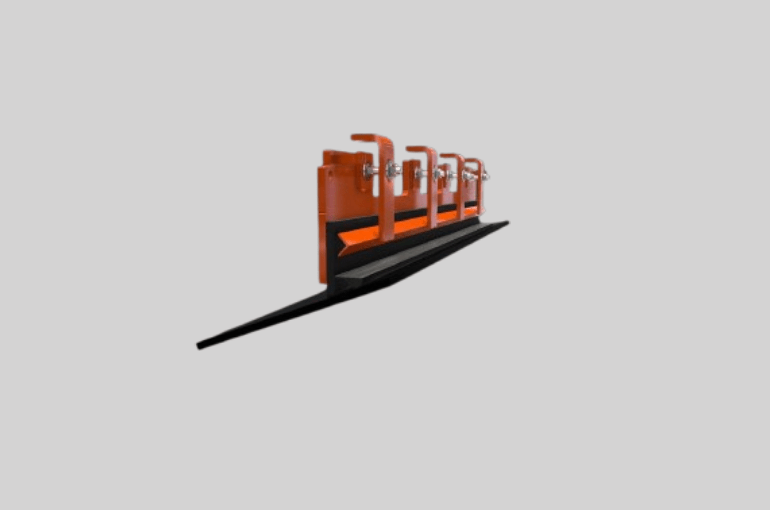

CleanScrape® Secondary Cleaner

The CleanScrape® Secondary Cleaner features a stainless steel assembly with independent 6-inch blades equipped with carbide tips. Supported by spring-loaded arms, the blades rotate and adjust to maintain consistent pressure, absorb obstructions, and safely arc during belt rollback, adapting to belt undulations.

Primary Belt Cleaners

Martin Engineering’s durable belt cleaners are built from high-quality materials, designed for optimal performance on conveyor belts up to 120 inches wide and speeds up to 2,000 fpm. As a leader in high-performance urethane development, Martin Engineering ensures cleaner, safer, and more productive conveyor systems. Our easy-to-maintain belt cleaners feature replaceable blades, and our team offers expert advice on bulk material handling solutions.

Secondary Cleaners

Martin Engineering’s high-performance secondary cleaners eliminate fugitive material and carryback, installed just after the discharge pulley to capture any residue missed by the primary cleaner. These durable, efficient cleaners can be used on high-speed belts of various widths, and additional units can be installed for thorough cleaning. Our expert technicians are available to assist with product selection and bulk material handling needs.

Specialty Cleaners

Includes belt washing systems, food-grade belt scrapers, water cleaners, high-temperature cleaners, brush cleaners and more.

| Filter By | Image | Product | Max Belt Speed | Max Belt Width | Pulley Diameter |

|---|---|---|---|---|---|

| Compatible With Reversing Belts or Roll Back |  Specialty Cleaners-4-enco.pk | Food Grade Cleaner | 200 fpm (1 m/sec) | Up to 48 in (800-1000 mm) | 6-10 in (152-250 mm) |

| Corrosive Conditions |  Specialty Cleaners-1-enco.pk | H2O Cleaner | 750 fpm (3.8 m/s) | Up to 84 in (2000-2200 mm) | |

| Max Belt Speed |  Specialty Cleaners-3-enco.pk | Brush Cleaner | 500 fpm (2.5 m/s) | Up to 72 in (up to 2000 mm) | |

| Max Belt Width |  Specialty Cleaners-2-enco.pk | Chevron Cleaner | 750 fpm (3.8 m/s) | Up to 96 in (up to 2400 mm) | |

| Max Temperature |  Specialty Cleaners-enco.pk | Washbox™ Cleaning System | 750 fpm (3.8 m/s) | Up to 84 in (2000-2200 mm) | |

| Pulley Diameter |

Martin® Replacement Blades deliver top value with free tensioners and mainframes.

Unlike off-the-shelf options, Martin Engineering custom-designs and builds advanced molding machines specifically for producing high-performance urethane blades. These machines ensure precision, consistency, and superior durability, all while being monitored and adjusted remotely for optimal quality control. With locations around the globe, Martin Engineering guarantees customers will receive belt cleaner blades that meet the highest industry standards, no matter where they are.

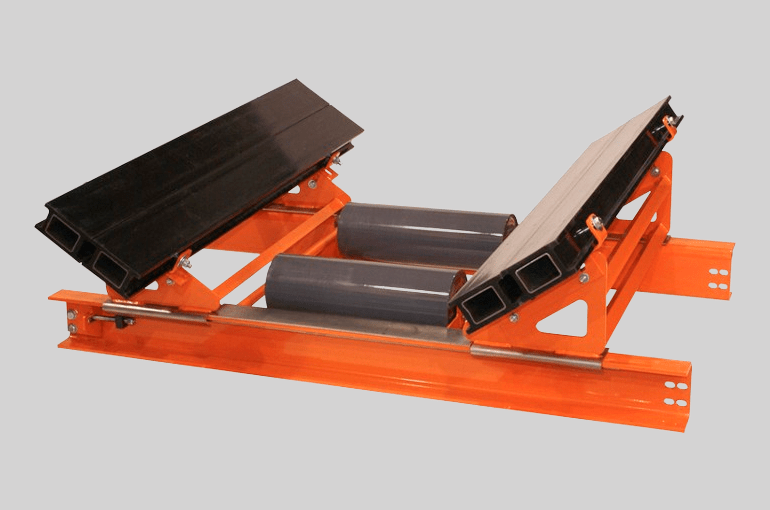

Transfer Point Solutions

Keep conveyor systems aligned and working perfectly!

Transfer points are crucial for conveyor efficiency but can be complex to engineer. With decades of experience, Martin Engineering offers durable, long-lasting transfer point solutions that improve conveyor performance, even in the toughest conditions.

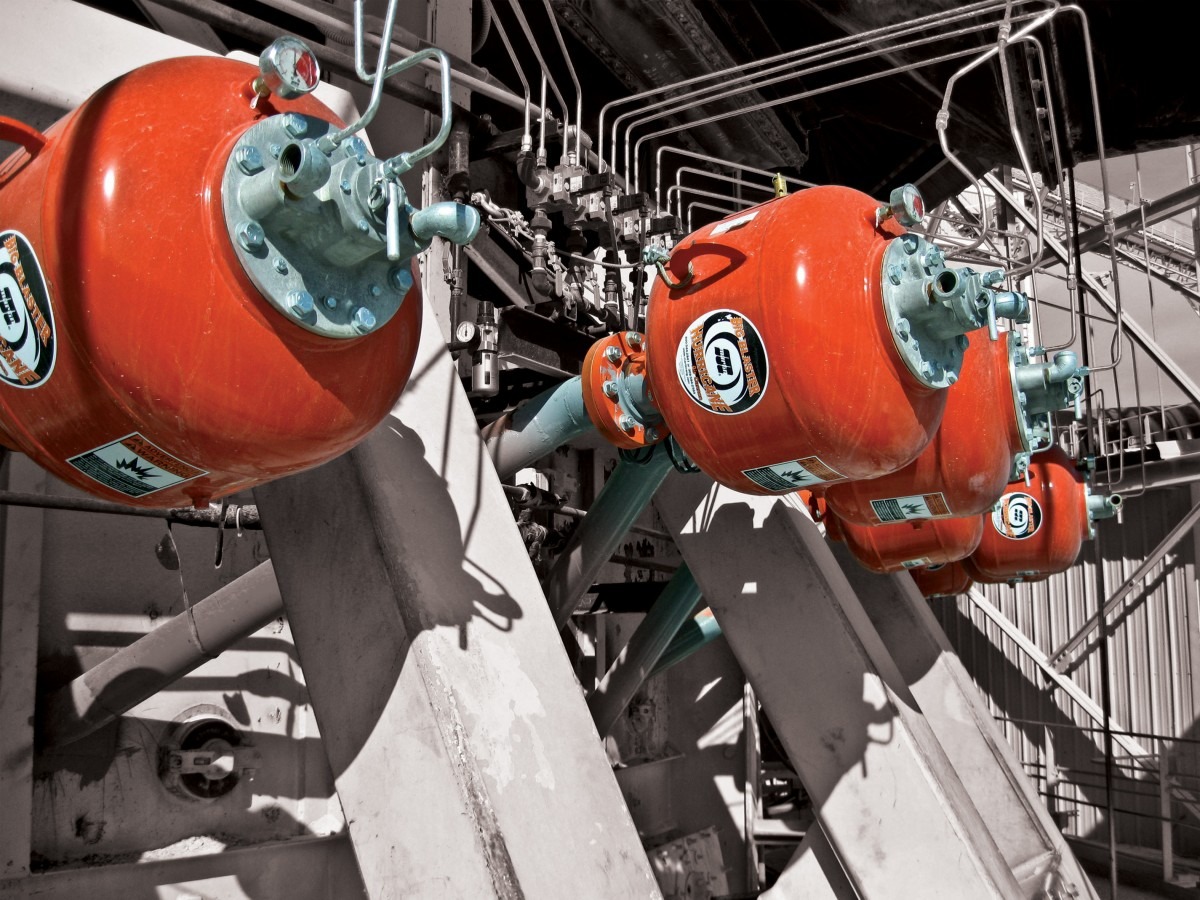

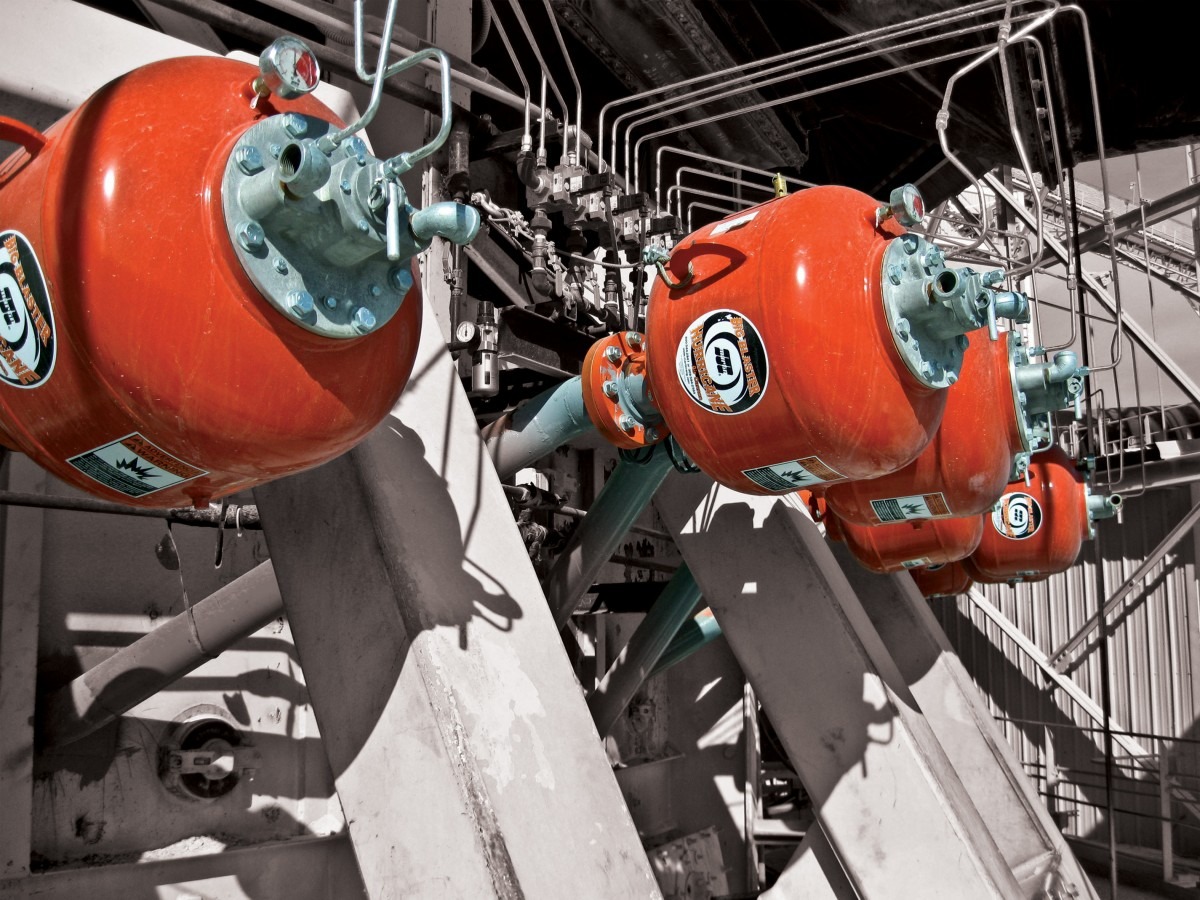

Air Cannons Solutions

Keep material flowing efficiently from start to finish!

At Martin Engineering, we help maximize profits by minimizing downtime with air cannons that clear material build-ups using bursts of air. Our innovative nozzles allow easy cleaning or replacement without removing the entire cannon. We also manufacture industrial vibrators for bulk material handling, ideal for applications with small particles or temporary installations like dump trucks.

Vibration

When the flow of material gets stuck, shake it loose!

For years, bulk material storage has posed challenges like bridging, ratholing, and arching, leading to production delays. Traditionally, operators used methods like water, air lances, or even sledgehammers to dislodge blockages. To address these issues proactively, Martin Engineering developed the industrial vibrator in 1944, providing a safe and efficient solution to enhance material flow and prevent blockages.