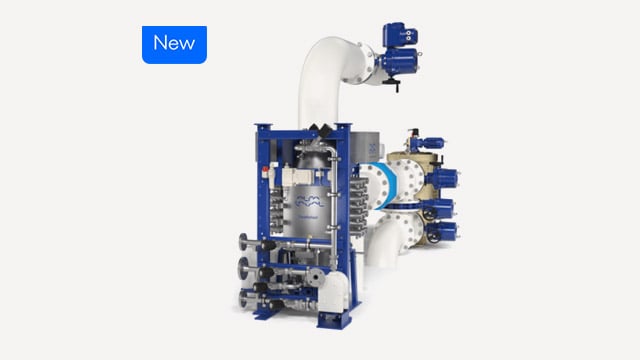

PureBallast 3

PureBallast 3

PureBallast 3 Ultra provides superior biological disinfection for fresh, brackish, and marine waters. Its expanded UV reactor sizes ensure optimal power efficiency, reducing energy use by up to 19% for specific flows. The compact design integrates the filter, CIP unit, and pressure monitoring into the UV reactor.

Available from Q3 2025, it handles flows of 42–3000 m³/h with optional ATEX and IECEX certification (Zone 1, IIC, T4).

Our portfolio for deliveries before Q3, 2025

PureBallast 3 Compact

This skid-mounted solution is designed for smaller ballast water flows, featuring easy installation due to its compact footprint and reduced piping.

- Ballast Flow: 32-300 m³/h

- Type: Skid-mounted, plug-and-play module

- Feature: Flexibly positioned electrical cabine

PureBallast 3 Compact

is the ideal choice for most vessels. Delivered as loose components, it maximizes space savings and installation flexibility

Ballast flow 32-1000 m3/h

- Complete installation freedom

- Minimized system footprint

PureBallast 3 Compact

Offers a broad range of reactor configurations and technical options for vessels in non-hazardous environments.

- Handles ballast flows from 500 to 3000 m³/h

- with capabilities up to 6000 m³/h using a dual system.

PureBallast 3 Compact

gives vessels with explosive environments redundant safety features and high flexibility. The power supply can be placed outside the hazardous zone.

Ballast flow 250-3000 m3/h

- ATEX and IECEX. Zone 1, IIC and T4

- Up to 6000 m3/h with dual system

Oil/gas-fired steam boiler

ENCO offers one of the most extensive product ranges in marine boilers. Our expertise dates back to 1919 when the first marine boiler was designed at Aalborg Shipyard in Denmark. Boilers on ships are utilized for supplying steam for various processes, including pumping, heating, cooling, cleaning, and providing hot water for accommodation

Our portfolio for deliveries before Q3, 2025

Aalborg 3-Pass

The Aalborg 3-Pass is an oil and gas-fired industrial boiler designed and optimized to incorporate all of ENCO’s technical and innovative expertise in every detail, both inside and out.

Aalborg D

Aalborg D is a high performance oil-fired marine boiler. It is intended for steam or hot water production. The boiler is built for lifelong reliability and low maintenance costs.

Aalborg HPNC

For supplying steam needed in deodorization processes and the physical refining of oils and fats.

Aalborg Mini 3-Pass

The Aalborg 3-Pass Mini boiler is a gas, LFO or dual fuel industrial boiler with a 0.5-2.5 ton/hour steam capacity and a design pressure up to 21 barg.

Oil/gas-fired composite steam boiler

On smaller vessels, a composite boiler can provide a cost-effective solution by saving space and minimizing pumping requirements. The ENCO OC-TCi is a plug-and-play option available in single-inlet or multiple-inlet configurations, capable of being fueled by either oil or exhaust gas.

Exhaust gas economizer

Exhaust gas economizers, positioned after diesel engines, and waste heat recovery units, used with gas turbines, are unfired systems that capture the otherwise wasted heat from exhaust gases. This recovered heat is utilized to generate energy or provide heating.

Aalborg AV-6N

The Aalborg AV-6N is a durable and highly efficient boiler featuring gilled water tubes, designed to enhance a plant’s overall performance by optimizing the recovery of exhaust gas heat.

Aalborg EGR-HPE

High-pressure economizer for EGR waste heat recovery

Aalborg H/HW

The Aalborg H/HW boiler is specifically designed for waste heat recovery from gas or diesel engines, featuring a straightforward and highly reliable construction.

Aalborg Micro

The Aalborg Micro is a compact exhaust gas heat exchanger/ steam generator, designed for waste heat recovery from gas/MDO/HFO engines and gas turbines.

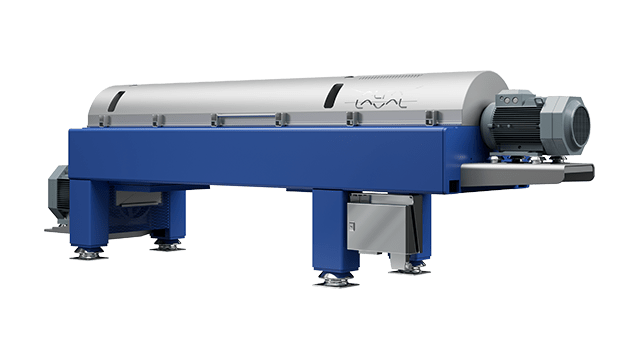

Decanters

ENCO decanter centrifuges provide efficient solid-liquid separation in a single continuous process. Gain a competitive edge with high-performance separation that yields high-quality, clarified products with greater commercial value. Make an impact by recovering valuable raw materials while minimizing energy consumption and reducing your environmental footprint and waste management costs through our advanced industrial decanter centrifuge solutions and services.

PureSOx

As the marine industry continues to evolve, there are compelling reasons to select a SOx scrubber. ENCO PureSOx provides cost-effective compliance with global fuel sulfur limits, as well as regulations in the growing number of Emission Control Areas (ECAs). Effective in both open-loop and closed-loop scrubbing, PureSOx can be supplied as a hybrid scrubber system featuring both operational modes. Additionally, it is supported by ENCO’s extensive experience and global service network.

Enhance product safety and boost productivity with ENCO's automation and control systems.

ENCO’s automation and control systems oversee equipment and processes, regulating flow rates and validating the operation of valves, pumps, and tank cleaning machines in hygienic fluid handling systems. Our offerings include valve sensing and control units, intelligent monitoring systems, and tank cleaning validation. The advantages? Achieve up to 90% savings in cleaning media costs by using less water and energy, alongside increased uptime, productivity, product safety, and extended equipment service life. This ultimately results in a lower total cost of ownership for industries such as dairy, food, beverage, personal care, and pharmaceuticals.

All automation and control systems

Cleaning validation

Our cleaning validation instruments provide a trusted and effective solution for enhancing quality assurance in tank cleaning processes.

Condition monitoring

Intelligent predictive maintenance systems monitor the condition of essential rotating equipment, like pumps, minimizing the risk of unexpected failures while enhancing uptime and productivity.

Sensing and control

Maximize production uptime and safety, regardless of process conditions, with a broad portfolio of valve automation solutions from Alfa Laval.

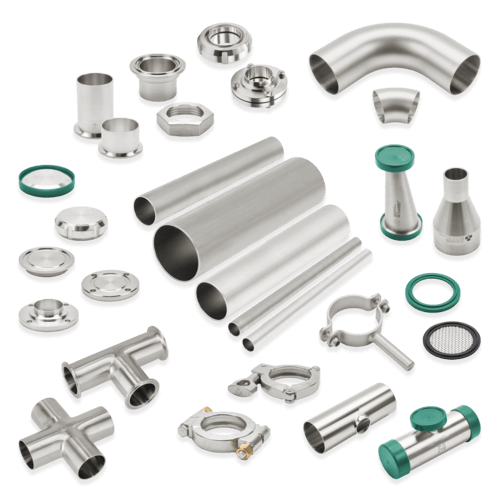

Process connections are crucial. Opt for ENCO tubes and fittings.

Hygienic tubes and fittings are crucial for connecting equipment and optimizing flow in process lines. Improve safety, uptime, and productivity with ENCO’s stainless-steel tubes, fittings, bends, tees, and reducers. Built to meet high standards for material strength, surface quality, microbial resistance, and cleanability, our range includes hygienic and UltraPure options designed for the food, biotech, and pharmaceutical industries where hygiene is essential.

Hygienic tubes

Count on ENCO hygienic tubes for contaminant-free connections in your hygienic processing systems.

Hygienic fittings

For contaminant-free connections in your hygienic and high-purity processing systems, trust ENCO hygienic fittings.

UltraPure tubes

Ensure optimal process safety with ENCO Tri-Clover® UltraPure tubes.

UltraPure fittings

Count on ENCO Tri-Clover® UltraPure fittings for exceptional safety, cleanliness, traceability, and product quality in your high-purity processes.

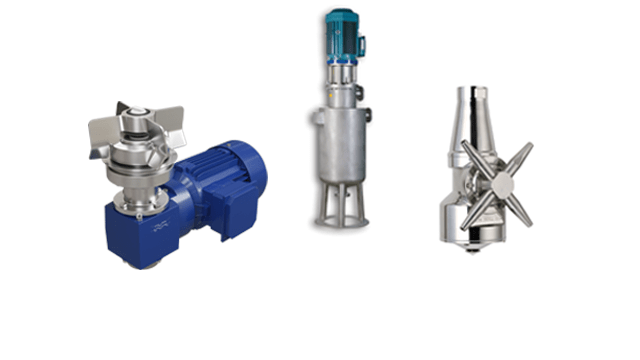

Knowledge-based mixing equipment

ENCO, a leading supplier of mixing equipment for hygienic industries, offers a range of mixers and agitators designed for optimal efficiency. Our solutions minimize water and energy use while ensuring high-quality product blending. Easy to install and maintain, they cater to the dairy, food, beverage, and pharmaceutical sectors.

Agitators

Our tank agitators feature a flexible, modular design that allows you to customize a mixing solution to meet your specific needs.

Powder mixers

Our mixers enable you to select the ideal mixing method, resulting in improved energy savings, enhanced cleanliness, and increased process efficiency with reduced processing time.

Tank mixers

Enhance uptime and yield with ENCO tank mixers designed for hygienic and aseptic applications.

Transfer your process fluids with ENCO's hygienic pumps.

Centrifugal pumps

ENCO centrifugal pumps enhance product quality and productivity in hygienic applications while ensuring high efficiency and energy savings.

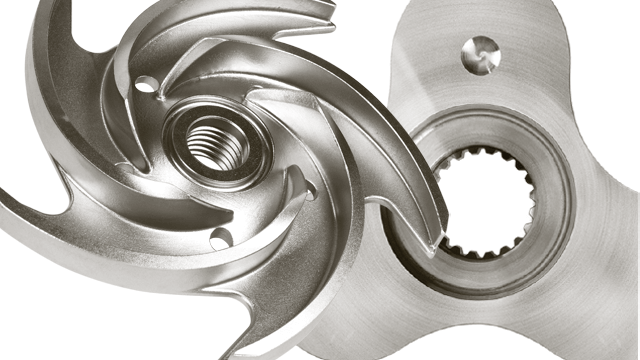

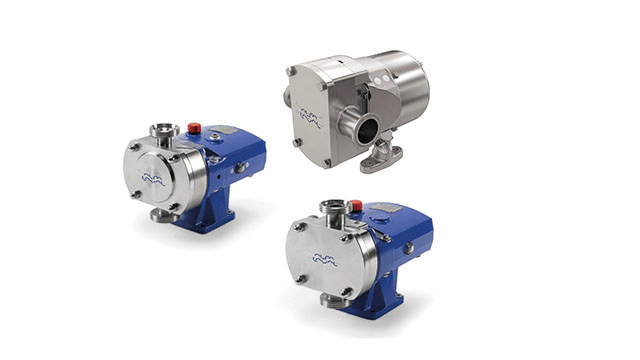

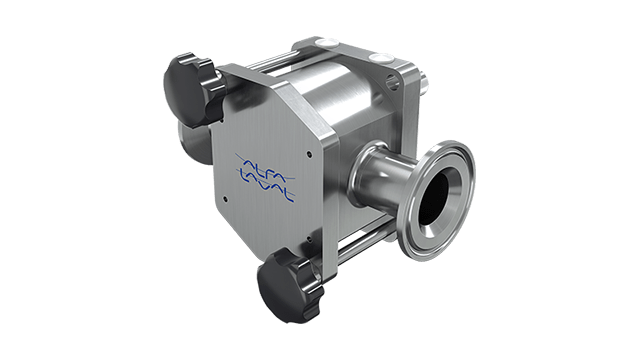

Circumferential piston pumps

ENCO circumferential piston pumps offer an ideal combination of high efficiency, excellent hygiene, and easy maintenance.

Rotary lobe pumps

ENCO rotary lobe pumps provide reliable performance with gentle pumping action for low, medium, and high-viscosity media.

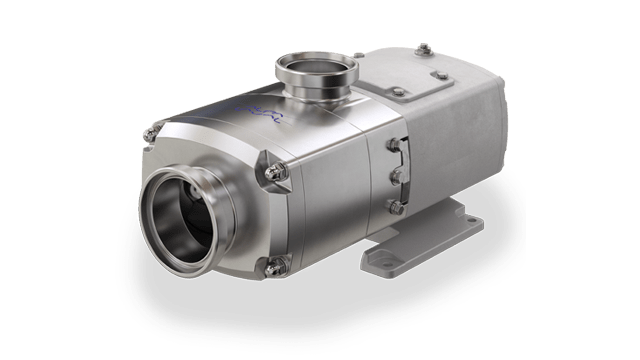

Twin Screw

The ENCO Twin Screw Pump is engineered for process flexibility, ensuring strict hygienic standards while effectively managing product transfer and Cleaning-in-Place (CIP) operations.

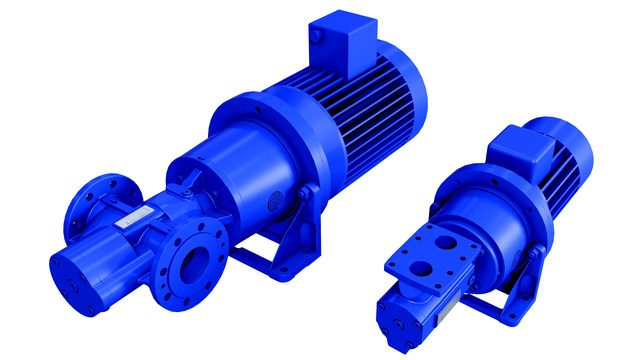

Three screw pumps

Three screw pumps

M Gear

The ENCO M Gear Pump efficiently transfers low-volume, clean fluids for dosing and filling applications.